But before they can enjoy the whiter, brighter, more beautiful smiles they demand, there’s a prerequisite: a clean tooth surface, free of bacterial plaque and stains.

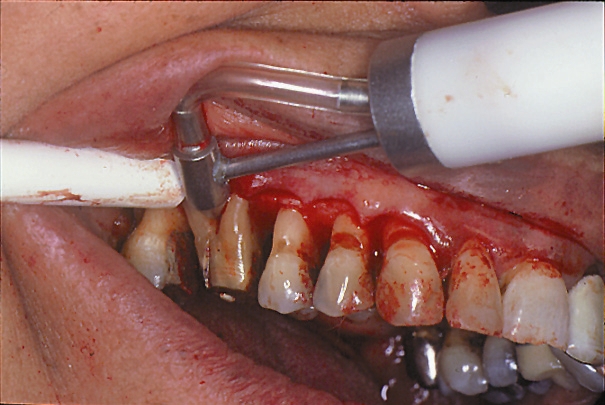

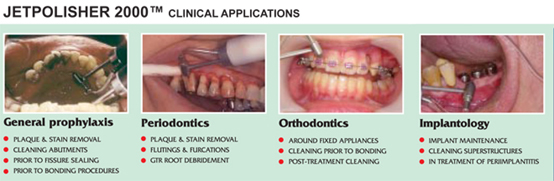

Traditionally, a rubber cup and fluoridated prophy paste method has been used for plaque and stain removal. However, this technique has obvious limitations in areas of crowding, around orthodontic fixed appliance and of course, in areas of limited access such as under and around fixed multiple unit restorations.

Early Years of Air Polishing

Air polishing was developed in the early 1970s as a technique for fast and efficient removal of extrinsic stains, plaque and other soft deposits from the teeth. It was designed to replace the prophy cup method and has been shown to save more than 50% of the clinical time spent on this tedious procedure. The technique was widely acclaimed when introduced, but this initial enthusiasm was somewhat tempered when it was found that the early technology resulted in frequent clogging problems with the system and the need for frequent servicing and maintenance.

Air polishing units typically generate a stream of pressurized air, carrying specially graded particles of a mild soluble abrasive, such as sodium bicarbonate. The abrasive is directed, in the presence of a stream of water, at a tooth surface to be cleaned. The mixture of water and powderladed stream occurs on the tooth surface and forms a “slurry” that is responsible for the cleaning action.

Drawbacks of Conventional Units

In most currently available units, the water stream emits through a separate nozzle that may be concentric to that of the powderladen air stream nozzle. The resulting buildup of crystalline anhydrous sodium bicarbonate deposits in the lumen of the air/powder nozzle results in clogging. Several attempts have been made to overcome this, including the introduction of a ‘bleed air stream’ that flowed constantly through the air/powder nozzle and changes in the chemical composition or physical nature of the powder

More recent technology produces a slurry by introducing the water stream into the powder-laden air stream, within the spray head at a critical moment, to produce a fully homogeneous stream that is emitted from a single nozzle. This stream technology configuration has not only been shown to prevent nozzle clogging by preventing the buildup of deposits, but also results in a much more efficient cleaning action because the slurry is formed prior to emission. Air polishing devices were originally designed to be standalone tabletop units. They have been considered to be the equipment of choice for the hygiene department, sometimes being combined with ultrasonic scaling devices. They offer a large powder chamber holding enough powder for multiple treatments, along with the convenience of a lightweight, fully autoclavable handpiece design. They are activated by a dedicated foot control that can select either a polishing or rinse mode and they require connections to water, air and electrical outlets. As such, they are normally allocated to a particular treatment room.

Air Polishing Advantages

There is increasing awareness among clinicians —periodontists, orthodontists, prosthodontists and restorative dentists alike—that having a simple, easily transportable air polishing unit can reduce the tedium of stain and plaque removal for many procedures. For example:

Pencil Type Units –- A Step In The Right Direction

Some current handheld air polishing devices connect directly to your dental unit’s handpiece tubing. Activation of the unit’s foot control generates the water and air supplies for the device. These “pencil-type” devices are of limited use in a busy hygiene office, but can be easily transported between operatories, conveniently stored, and can be ready for action on short notice. Because they have integral powder reservoirs with limited powder capacity, they are mostly not fully autoclavable, and the drag of the powder reservoir makes long-term use inconvenient and tiring. In addition, there is considerable inconvenience associated with having to constantly refill the powder reservoir.

Deldent’s New Generation – The Ultimate Solution

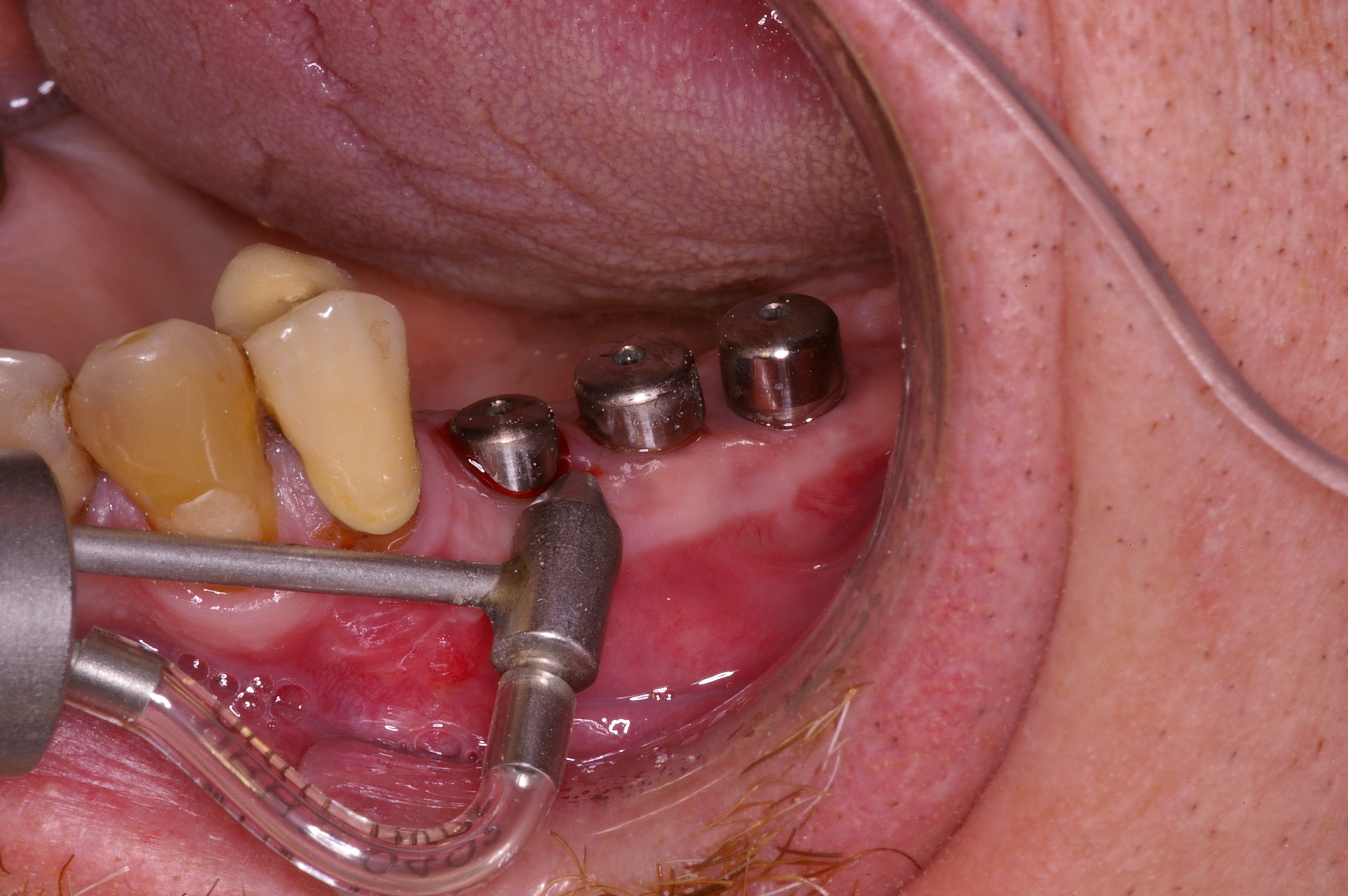

Deldent air polishers incorporate Homogeneous Stream Technology (H.S.T.®) that eliminates nozzle clogging. These devices have been cleared by the FDA for cleaning around titanium implants. The H.S.T. slurry begins to soften the powder particles before they impact the implant surface, and independent research has shown this system causes no damage to titanium implant and transmucosal elements. While still retaining the convenience and portability of connecting directly to the dental unit’s handpiece tubing, these devices are designed so that the powder reservoir with a capacity for multiple prophy treatments is separate from the fully autoclavable handpiece. This eliminates the drag associated with handheld units. The new H.S.T.- equipped units are compact, taking up minimal workspace. They can also be quickly disconnected for storage or for transportation from one workstation to another. They incorporate the advantages of the standalone tabletop units, offering both rinse and polishing modes, without the disadvantages. These units are suitable for the busy hygiene practice but are alsoideal for the doctor. With a new generation H.S.T. air polisher, you can enhance clinical procedures and increase patient satisfaction.

Deldent’s airpolishers have been cleared by the FDA for cleaning around titanium implants.