Date – 03/03/2011

Clinical application of sandblasting using the MiniblasterTM from Deldent Ltd

Suitable for intraoral use, the MiniblasterTM is designers to enhance adhesive dentistry procedures.

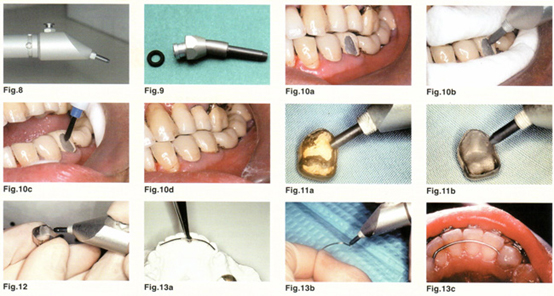

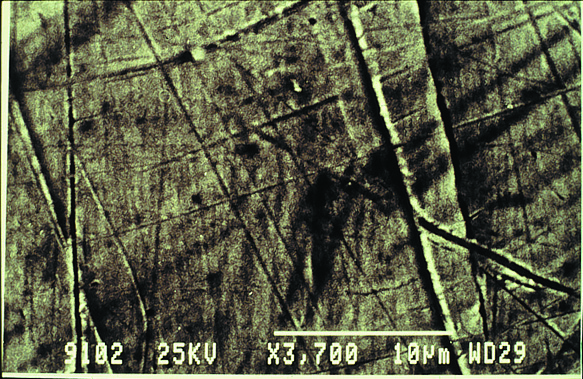

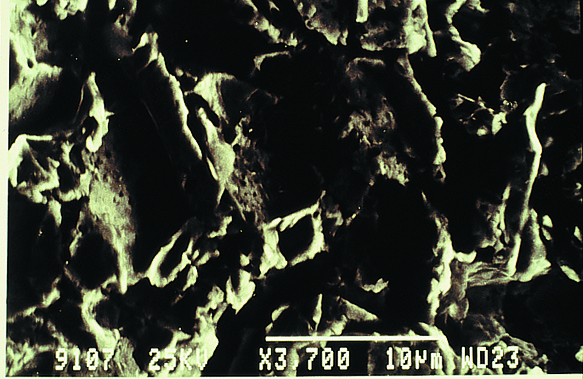

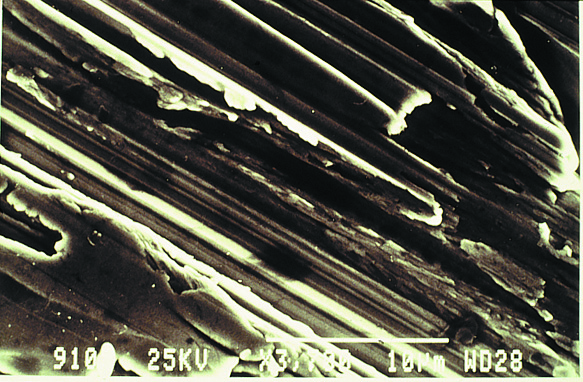

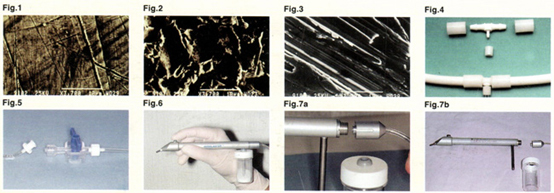

Use of the MiniblasterTM is said to significantly increase the micro – retention of bonding surfaces. The increase in surface microroughness that can be achieved by sandblasting can be seen in 3,700 XSEM micrographs. Figure 1 shows polished gold, and Figure 2 shows the surface after sandblasting. The resulting retention significantly is greater than that achieved by the grooves produced by roughening with a bur (Figure 3).

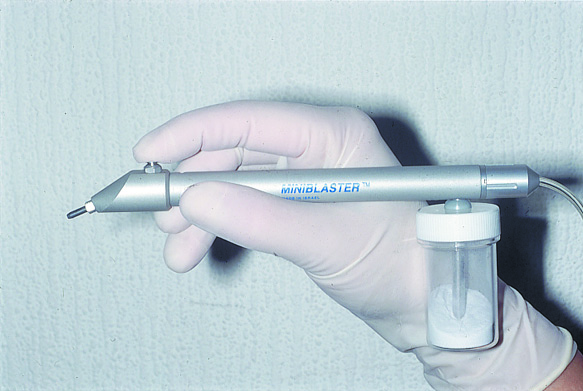

The MiniblasterTM can be installed with the installation kit supplied with the unit (figure4). For maximum efficiency, the unit should be operated at 80-100 psi. An in- line, high-pressure stopcock is provided to permit the sandblaster to be readily disconnected from its air supply line after installation (Figure 5), facilitating transport from one operatory to another. Additional installation kits are available.

The index-finger-operated control valve on the top of the unit (Figure 6) is ergonomically designed and positioned. The control button makes the sandblaster equally simple to operate by either right or left-handed operators.

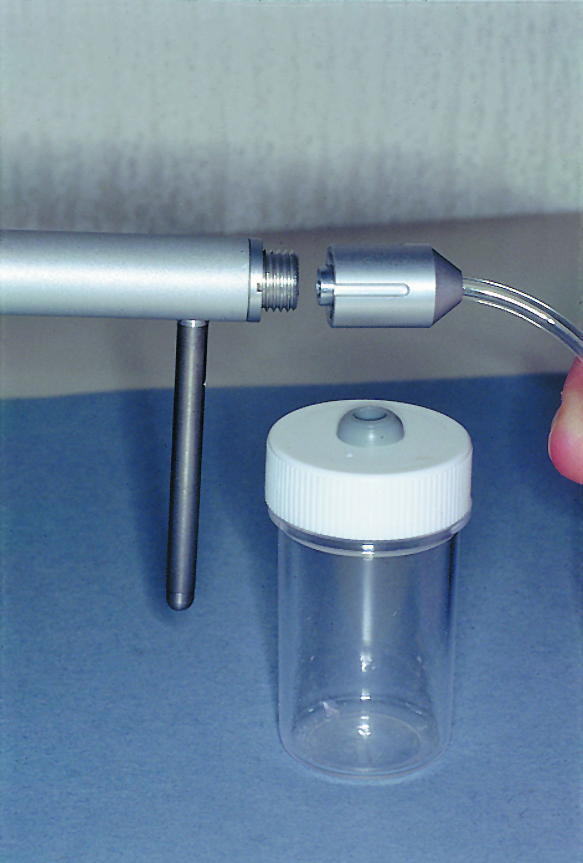

The entire unit is autoclavable. Following disconnection of the rear connector and removal of the powder chamber (Figure 7a), all components can be prepared for sterilization packaging in the usual manner (Figure 7b).

The spray head rotates via a unique ratchet system for optimal directional control (Figure 8).

A tungsten carbide extension spray nozzle with 360° that screws over the standard nozzle is available (Figure 9). This extension nozzle is rarely needed, but can offer access to areas not easily reached by the standard nozzle.

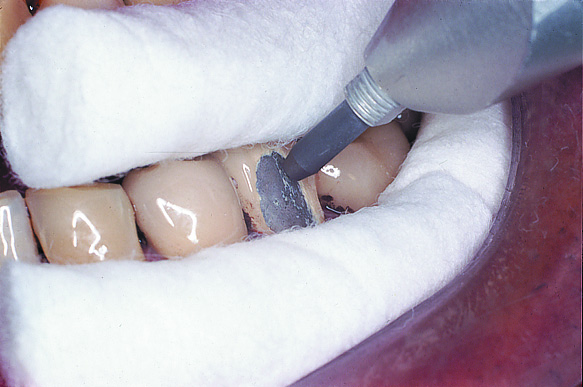

The MiniblasterTM can be used for surface preparation prior to bonding to all dental materials including : Precious, semiprecious, and nonprecious metals; porcelain; composite; and resin materials. In principle macro retention such as under-cuts should be employed where possible in conjunction with the micro retention produced by the MiniblasterTM . Although 50-micron aluminum oxide is abrasive of choice for routine use, 90-micron can be employed for more aggressive work and cement removal. Figure 10a-d shows the intraoral repair of a fractured porcelain facing. Pre-op conditions are illustrated in figure 10a, sandblasting in Figure 10b, and bonding application in Figure10c. An opaquing material should be applied to mask any exposed metal. Cotton rolls or a rubber dam should be used for area isolation. Figure 10d shows the repair 12 months later.

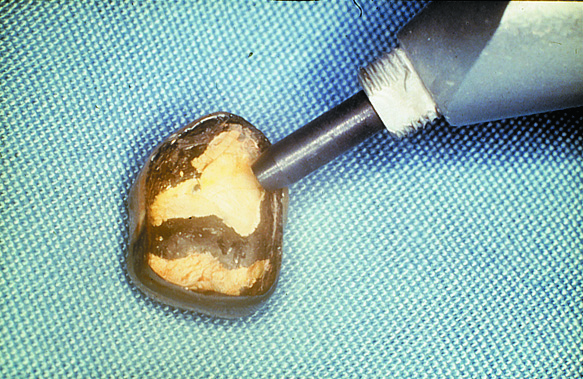

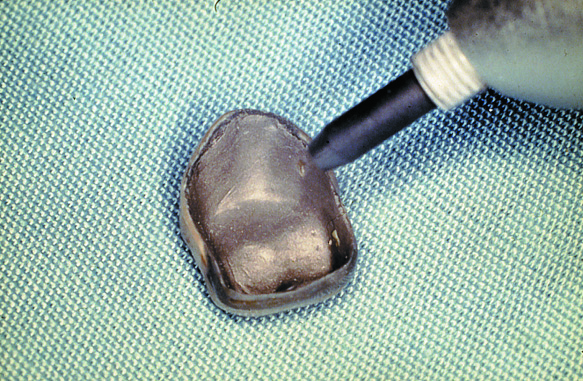

Figure 11a and 11b shows removal of cement from a crown prior to recementation.

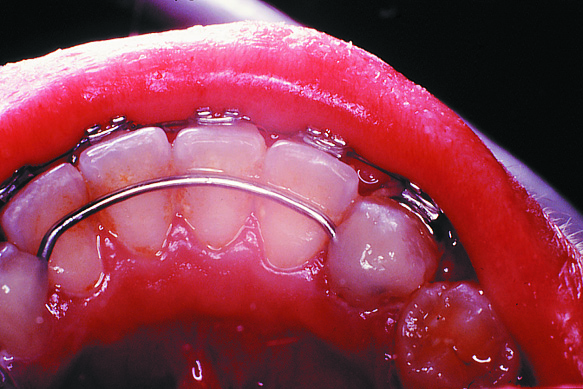

Sandblasting of orthodontic bands is said to significantly improve their retention (Figure 12).

Sandblasting of detached orthodontic brackets will remove composite and allow rebonding. The stages in preparation of a simple orthodontic lingual retainer are: Wire adaptation (Figure 13a) followed by sandblasting (Figure 13b). The bonded retainer is shown in Figure 13c.